HORIZONTAL LIFE LINES WITH RAIL

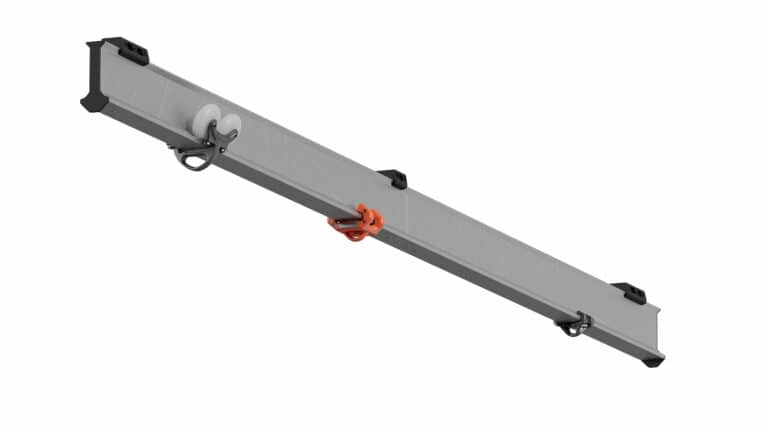

The CONEKT horizontal rail lifeline is a height access system for facade maintenance and cleaning.

Depending on the configuration, a rope access technician or a basket can be suspended from the rail. The rail allows movement across the area by means of a mobile anchor point.

The system is ATEX certified for potentially explosive environments. Rail lifelines are compliant for the following uses:

- NAV2 mobile fall arrest anchor point;

- Suspended work trolley NAV7;

- NAV4 motorized horizontal translation trolley;

- Cart operated manually by a rope and pulley;

- AISI304 steel roller.

This system is the most cost-effective in terms of operating costs. Optionally, the system can be painted in the desired color to match the building’s architecture.

THE advantages of CONEKT cable lifelines

- Rigid, continuous, and stable support throughout the entire course

- Easy-to-clean OAD** anodized aluminum: water + soap

- 2 types of rails: standard and XL. Each is available in 3m and 6m sizes.

- Scattered efforts in the event of a fall

- Controlled deflection: in the worst case scenario, maximum deflection of 50 cm for standard rail / maximum deflection of 17 cm for XL rail => possibility of installing LDV rail at low heights

Conekt RAIL lifeline

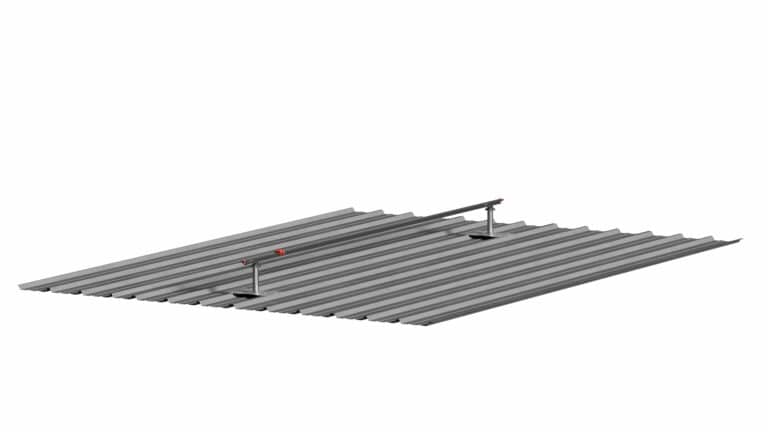

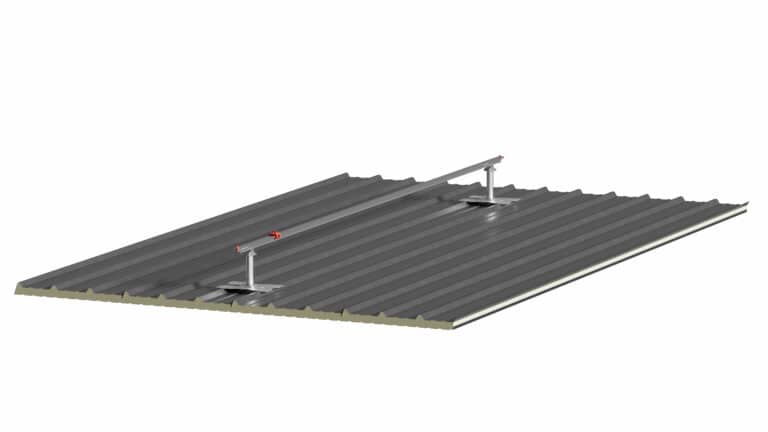

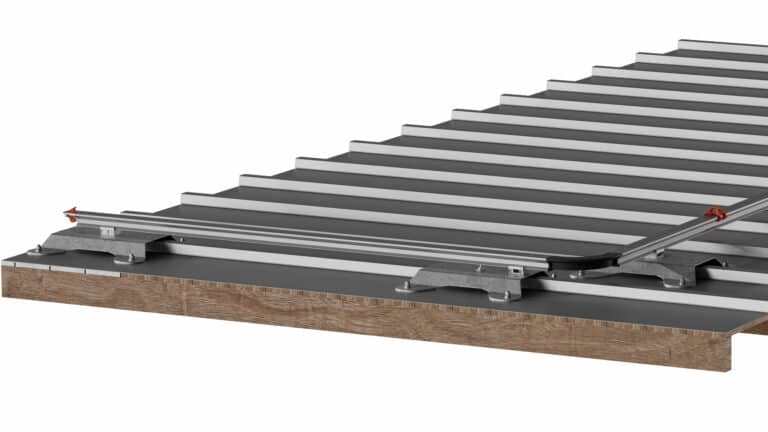

CONEKT dry rail lifeline system

The installation of a CONEKT rail lifeline on a dry tray is carried out using:

- PB1 or PB2 board, which you will choose depending on the wave width of your medium;

- the R25 short rail fastener to attach the rail directly to the plate or to a riser (PB250 tilting post or AD diabolo) if necessary.

Dry tray thickness ≥ 0.63 mm.

Center distance between fasteners: 6 m max.

Maximum of 4 simultaneous users.

Periodic verification at least once every 12 months:

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.

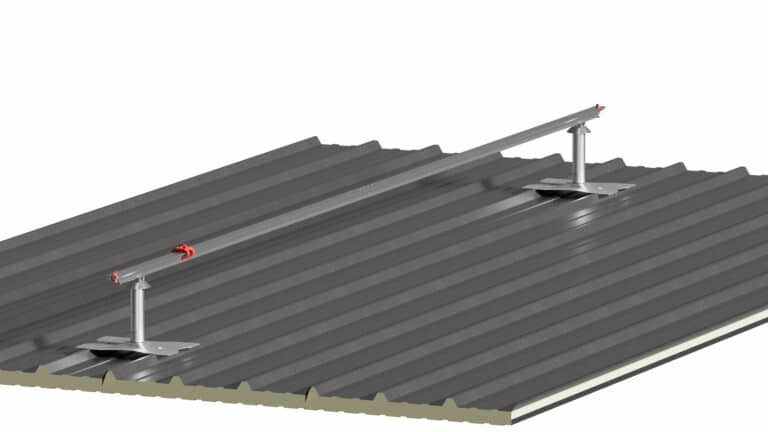

Rail lifeline on CONEKT sandwich panel

The installation of a CONEKT rail lifeline on sandwich panels is carried out using:

- PB1 or PB2 board, which you will choose depending on the wave width of your medium;

- the R25 short rail fastener to attach the rail directly to the plate or to a riser (PB250 tilting post or AD diabolo) if necessary.

Thickness ≥ 0.5 mm.

Center distance between fasteners: 6 m max.

Maximum of 4 simultaneous users.

Periodic verification at least once every 12 months:

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.

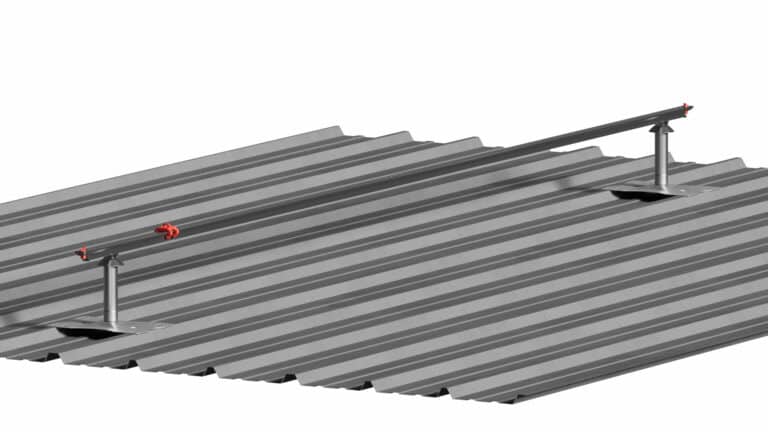

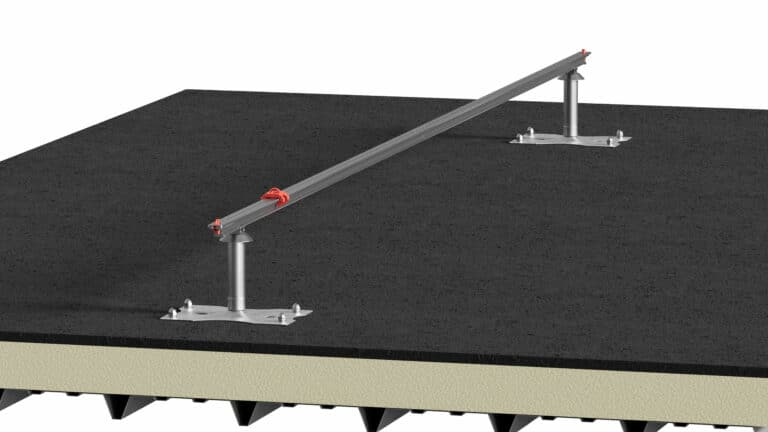

CONEKT rail lifeline on waterproof tray

The installation of a CONEKT rail lifeline on a waterproof tray is carried out using:

- PB2 or PB4 turntable, which you can choose depending on the type of media you have;

- the R25 short rail fastener and the PB250 tilting post to secure the rail to the plate.

Tray thickness ≥ 0.63 mm.

Center distance between fasteners: 6 m max.

Maximum of 4 simultaneous users.

Periodic verification at least once every 12 months.

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.

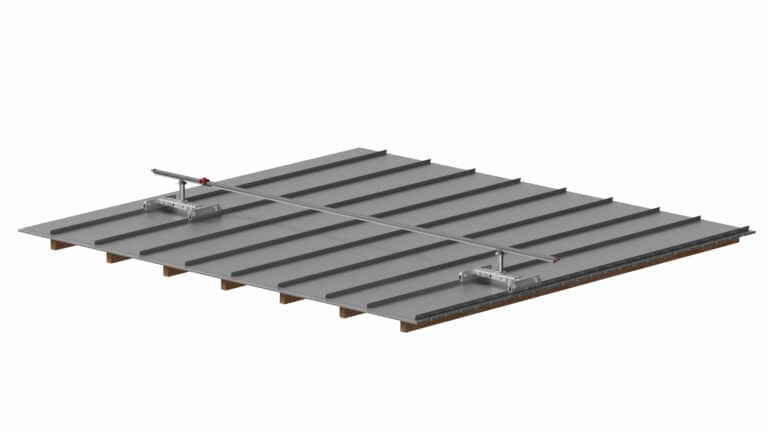

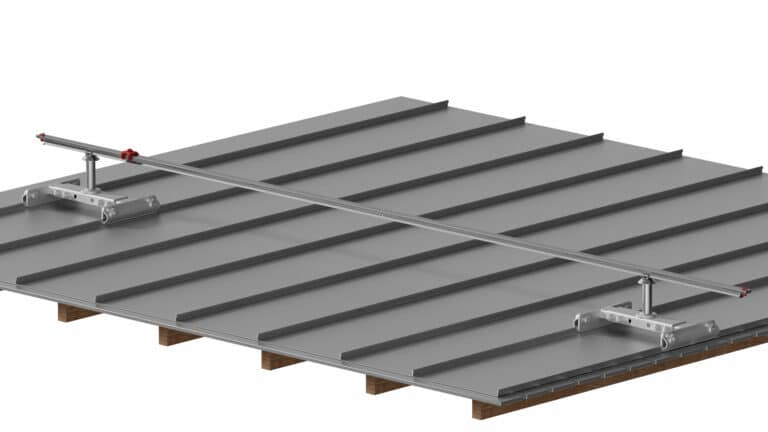

CONEKT standing seam rail lifeline

The installation of a CONEKT rail lifeline on standing seams is carried out using:

- the short ICJD L interface or the wide ICJD S interface dedicated to this type of support, which you will choose according to the spacing between the standing seams;

- the R25 short rail fastener to attach the rail directly to the interface or to a riser (PB250 tilting post or AD diabolo) if necessary.

Center distance between fasteners: 6 m max.

Maximum of 4 simultaneous users.

Periodic verification at least once every 12 months:

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.

CONEKT zinc roof batten rail lifeline

The installation of a CONEKT rail lifeline on zinc battens is carried out using:

- the ICZ interface dedicated to this type of media;

- the R25 short rail fastener to attach the rail directly to the interface or to a riser (PB250 tilting post or AD diabolo) if necessary.

Battens ≥ 12 mm – Zinc sheet.

Center distance between fasteners: 6 m max.

Maximum of 4 simultaneous users.

Periodic verification at least once every 12 months:

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.

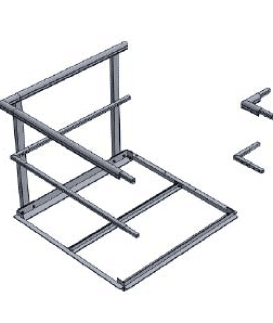

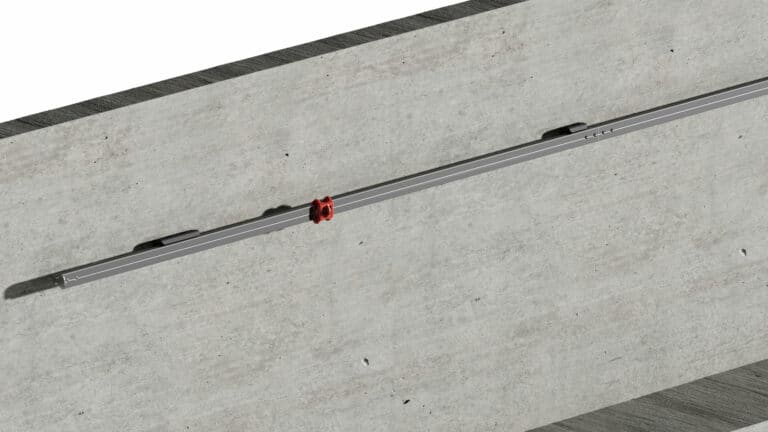

CONEKT concrete slab rail lifeline

The installation of a CONEKT rail lifeline on zinc battens is carried out using:

- the P300 rigid post or the P500 rigid post, depending on the desired clearance height;

- of the R25 short rail fastener for attaching the rail directly to the post.

It is impossible to add a riser to rigid concrete posts.

Center distance between fasteners: 6 m max.

Maximum of 4 simultaneous users.

Periodic verification at least once every 12 months:

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.

CONEKT concrete wall rail lifeline

The installation of a CONEKT rail lifeline on zinc battens is carried out using:

- the short R25 rail fastener or the wide R25XL rail fastener to attach the rail directly to the concrete wall;

- P300 or P500 rigid concrete posts if an extension is required.

Center distance between fasteners: 6 m max.

Maximum of 4 simultaneous users.

Periodic verification at least once every 12 months:

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.

CONEKT rail lifeline on steel structure

The installation of a CONEKT rail lifeline on zinc battens is carried out using:

- the CRA double frog and the SC frog support;

- the short R25 rail fastener to attach the rail directly to the mounting bracket or to a riser (AR joint or AD diabolo) if necessary. It is possible to stack risers and even add a custom-made tube if even more clearance is required.

In specific cases, depending on the ceiling support, it is possible to attach the rail directly using the R25XL wide rail fastener.

Ceiling use with standard or XL rail.

Center distance between fasteners with standard rail: 5 m max. If using hangers, fasteners should be placed every 2.5 m.

Center distance between fasteners with XL rail: 6 m, if suspension 5 m.

Maximum of 4 users simultaneously / 2 users if suspended.

Periodic verification at least once every 12 months:

- Rigid lifeline made of anodized aluminum;

- CONEKT rails and LDV components have no sharp edges that could damage ropes or cords.