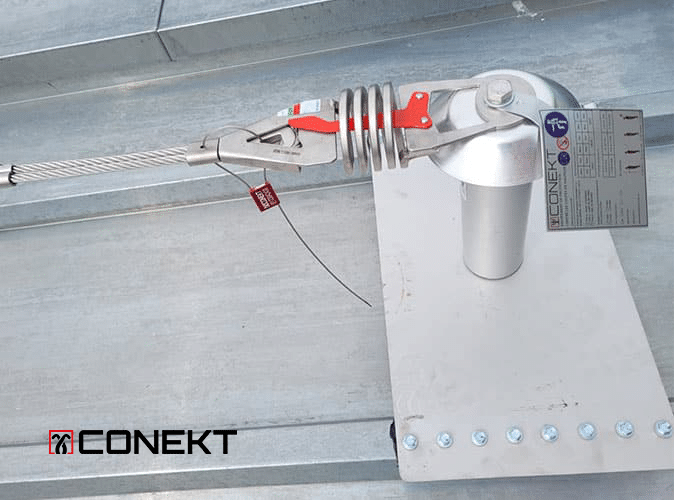

HORIZONTAL CABLE LIFELINES

CONEKT is a flexible and comfortable lifeline for securing all your movements at height. Cable lifelines can be adapted to most supports:

- Bac sec;

- Sandwich panel;

- Zinc roofing;

- Standing seam;

- OSB panel;

- Watertight container;

- Concrete wall;

- Steel frame.

There are two versions of cable lifelines: manual and automatic. Our system complies with current standards and is CSA Z259.16 certified.

THE advantages of CONEKT cable lifelines

- Flexibility and ease of movement for users

- Adapts to complex structures, easier to overcome obstacles

- Approved for 4 simultaneous users, 2 if the lifeline is used for suspended work.

- Ease of adding sections

- Competitive cost

- Range up to 49.2 ft (15 m) depending on installation

CONEKT Manual Lifeline

Dry container installation

The installation of a CONEKT cable lifeline on a dry tray is done using the PB2 plate, to which a riser (AD diabolo or PB250 tilting post) must be added.

Technical specifications to be met:

- Dry tray thickness ≥ 0.63 mm;

- Center distance between fasteners: 10 – 12 m max;

- Periodic verification at least once every 12 months.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.

Installation on sandwich panel

- Thickness ≥ 0.5 mm;

- Center distance between fasteners: 10 – 12 m max;

- Periodic verification at least once every 12 months.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.

Installation on waterproof tray

The installation of a CONEKT cable lifeline on a waterproof tray is carried out using the PB2 or PB4 plate, to which a PB250 tilting post must be added.

Technical specifications to be met:

- Thickness ≥ 0.63 mm;

- Center distance between fasteners: 10 – 12 m max;

- Periodic verification at least once every 12 months.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.

Installation on OSB board

The CONEKT cable lifeline is installed on OSB panels using the PB4 plate, to which a PB250 tilting post must be added.

Technical specifications to be met:

- Thickness ≥ 18 mm;

- Center distance between fasteners: 10 – 12 m max;

- Periodic verification at least once every 12 months.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.

Installation on standing seam

The installation of a CONEKT cable lifeline on standing seams is carried out using ICJD S or ICJD L plates specially designed for this type of support. You should choose the right plate according to the spacing between the standing seams. It is possible to add an extension (AD diabolo or PB250 tilting post) if necessary.

Technical specifications to be met:

- Use on flat or rounded standing seams;

- Zinc ⩾ 1 mm / Acier ⩾ 0,63 mm / Alu ⩾ 0,9 mm;

- Center distance between fasteners: 10 – 12 m max.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.

Installation on zinc battens

The installation of a CONEKT cable lifeline on zinc battens is carried out using the ICZ plate, which is specially designed for this type of support. An extension (AD diabolo or PB250 tilting post) can be added if necessary.

Technical specifications to be met:

- Thickness ≥ 12 mm – zinc sheet;

- Center distance between fasteners: 10 – 12 m max;

- Periodic verification at least once every 12 months.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.

Installation on concrete slab

The CONEKT cable lifeline is installed on concrete slabs using P300 and P500 rigid concrete posts, depending on the desired height of 300 mm or 500 mm.

Technical specifications to be met:

- Center distance between fasteners: 15m max;

- Periodic verification at least once every 12 months.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.

Wall mounting

A CONEKT cable lifeline is installed on a concrete wall using S12 or S13 wall end plates, which you can choose depending on the type of support.

Technical specifications to be met:

- Distance between crossbars: 15 m;

- Periodic verification at least once every 12 months.

For the automatic version, it can be used with two types of shuttles: openable A01 and captive A02.